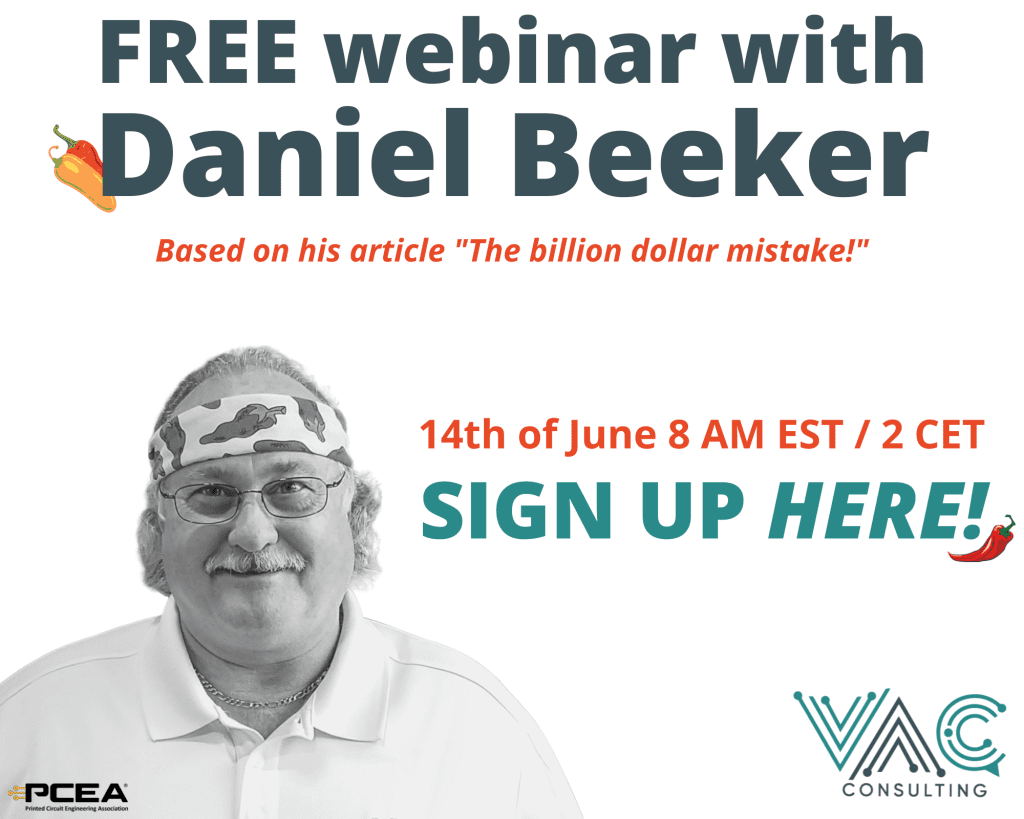

Daniel Beeker - The billion dollar mistake

About Daniel Beeker

Daniel’s unique approach to EMC is the result of many years of collaboration with one of the fathers of our industry, Ralph Morrison, whose foundation textbook, “Grounding and Shielding Techniques,” was published in 1967. Ralph’s science-based approach to design has formed the basis for Daniel’s design philosophy, which has resulted in consistent success in both his designs and those of his students. Daniel also attributes his success to his association with another industry leader, Rick Hartley. The influence of these two extremely knowledgeable mentors can be seen in the material Daniel presents and his passion for sharing this perspective with the engineering community.

Daniel is a perennial presenter at PCB East and West, as well as DesignCon and has done several webinars for Sierra Circuits. Daniel has written several articles on PCB design for EMC and Signal Integrity, and is an inaugural presenter for the newly formed PCB Africa webinar series.

Daniel was the first recipient of UBM Publishing’s 2017 Annual Creativity in Electronics (ACE) Award as the Embedded Systems Conference (ESC) Speaker of the Year and has been selected as a Keynote speaker at Altium Live 2017 in San Diego and Altium Live 2019 in Munich. Dan is a regular presenter at both PCB West and Embedded Systems conferences, as well as at IEEE EMC Society and NXP training events. Daniel was recently promoted to Technical Director at NXP and just awarded with Senior Member Status by the IEEE Society.

The billion dollar mistake

We all are involved with developing products that generate, control, and consume ELECTROMAGNETIC FIELD ENERGY. This is not what we are taught. Circuit theory suggests that electrical energy is made up of electrons moving in the conductors. Switches add conductors, and the current instantly starts to move in the loop. The wires carry the energy, and the load instantly responds to the flow of energy. WRONG!! Switches add new spaces, and the moving field carries the energy. It takes time for the field energy to move into that space. The moving field energy has no idea of what it is at the end of the new space. Field energy moving through a space is the current flow. The magic here is the displacement current flowing through the dielectric at the wavefront, completing the circuit. Fields do all the work. “Current flow” is a measure of moving field energy through a space. “Current flow” occurs in the space between the conductors that bound the dielectric. Some of the fields interact with the molecules in the outer surfaces of the conductors. This interaction consumes some of the field energy, hence a resulting voltage drop caused by this “resistance.” The consumption of field energy results in increased movement of the molecules, hence is converted to “heat”! The dielectric also consumes energy the same way unless it is a vacuum. Electromagnetic energy moves slower through a physical dielectric than through space. Field energy can only travel in space, not through matter. It takes TIME for the energy to go around the molecules it encounters. The higher the molecular density, the longer the path, hence, it takes the field longer to go from one place to another. Once created, EM field energy can only move from one space into another one as we intend, be converted into kinetic energy, or radiated into the surrounding spaces.

Abstract—Engineering teams worldwide are facing increasingly difficult challenges to design electronic products and achieve good signal integrity and compliance. However, the status quo had become to expect the design to fail EMC testing, not just once, but three, four, or as many as five times. Each time the design is sent to be retested, there is little confidence in success. This cycle is expensive in both the time it takes to redesign the product and the cost of expediting fabricating the new PCB and assembly. Add this to the cost of retesting the product, and the numbers add up very quickly. This expense and delay in product certification are not in the budget or the schedule. The expense directly affects the bottom line of the electronic supply company, but also affects the customers waiting for the product. Instead of designing the next big thing, teams are trying to fix the current one. As a result, billions of dollars are lost each year designing products that are expected to fail. – Author Daniel Beeker.